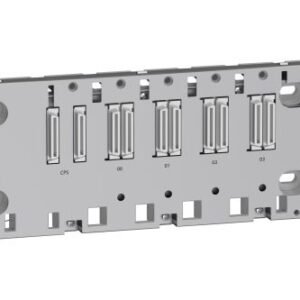

Schneider Electric ATV320 Series Variable Speed Drive, 1.1kW Power Rating, 13.8A Current Rating – ATV320U11M2CThis variable speed drive is designed to deliver efficient motor control tailored for various applications. With a compact format and DIN Rail mounting option, it supports asynchronous and synchronous motors, making it versatile for complex machinery. Measuring 105mm in width, 142mm in height, and 158mm in depth, this drive ensures seamless integration into existing systems.Features & Benefits

• Enhances automation capabilities for improved machine effectiveness

• Supports Profibus communication for seamless integration

• Energy-saving motor control reduces operational costs

• Features safe torque off (STO) for enhanced safety

• Equipped with an EMC filter for reduced electrical interference

• Adjustable acceleration/deceleration ramps for optimal performanceApplications

• Ideal for controlling asynchronous and synchronous motors

• Commonly utilised in various complex industrial machines

• Suitable for automation projects requiring variable speed control

• Applied in systems needing energy-efficient motor solutionsHow does energy-saving functionality affect operational costs?The energy-saving function optimises motor performance by adjusting frequency ratios, which leads to significant reductions in power consumption and lower operational expenses.What safety features are integrated into the design?The drive includes safe torque off (STO), which prevents unintended starts, and thermal protection to safeguard the device during overheating scenarios.How does the device support various communication protocols?With modular communication options, it supports protocols like Modbus Serial and Profibus, allowing for easy integration into diverse control systems and enhanced connectivity.What is the significance of its IP20 rating?The IP20 rating indicates protection against solid objects larger than 12.5mm, suitable for indoor installations where exposure to dust and moisture is minimal, ensuring optimal reliability in controlled environments.Can it accommodate high load applications?Yes, this drive can handle demanding applications with a nominal output current of 6.9 A, providing effective control for high load scenarios.

Automation & Control Gear

Order by WhatsApp

Compare

Electric Variable Schneider Speed Drive, 1.1 kW, 1 Phase, 230 V ac, 13.8 A, ATV320 Series – ATV320U11M2C

Schneider Electric ATV320 Series Variable Speed Drive, 1.

×

There are no reviews yet.